Pipeline Monitoring, Inspection and Repair

Front End Inspection with Back End Repair Solutions

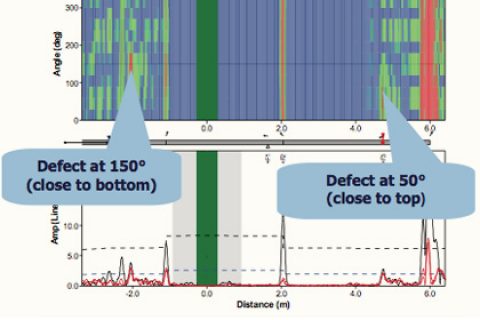

Applications of Long Range Ultrasonics using the GUL G3 (Focus Software) System

PMI now offer Front End Inspection Services as part of our continued commitment to offer a complete solution to pipeline monitoring and maintenance.

Rapid, full coverage screening of pipes

Especially cost effective in difficult to access locations:

- Sleeved road crossings

- Corrosion under insulation

- Wall penetrations

- Pipe racks

- Rope access

Sectors:

- Oil and Gas

- Petrochemical

- Offshore – Topside and Subsea

- Deserts & Tropics

- Colder regions – Alaska

Regular monitoring can drive Intelligent pigging programmes

Reporting

- Best used as a screening tool that is part of a more comprehensive testing strategy.

- Good at quickly determining which out of a series of inaccessible pipelines are most heavily corroded.

- Good at quickly locating areas of probable concern.

- All reports are submitted after careful analysis with full details of areas of concern.

PIMS: Permanently Installed Monitoring System

Special rings can be bonded onto the pipe permanently for use on any pipe including buried pipe.

Back End Repair Solutions

Pipeline Damage Assessment & Repair

- 3x Reinforce kits

- 3x Stopkits for emergency leak repairs

- Epoxy Shells

- Composite Repairs

- Full stopple & Bypass operation